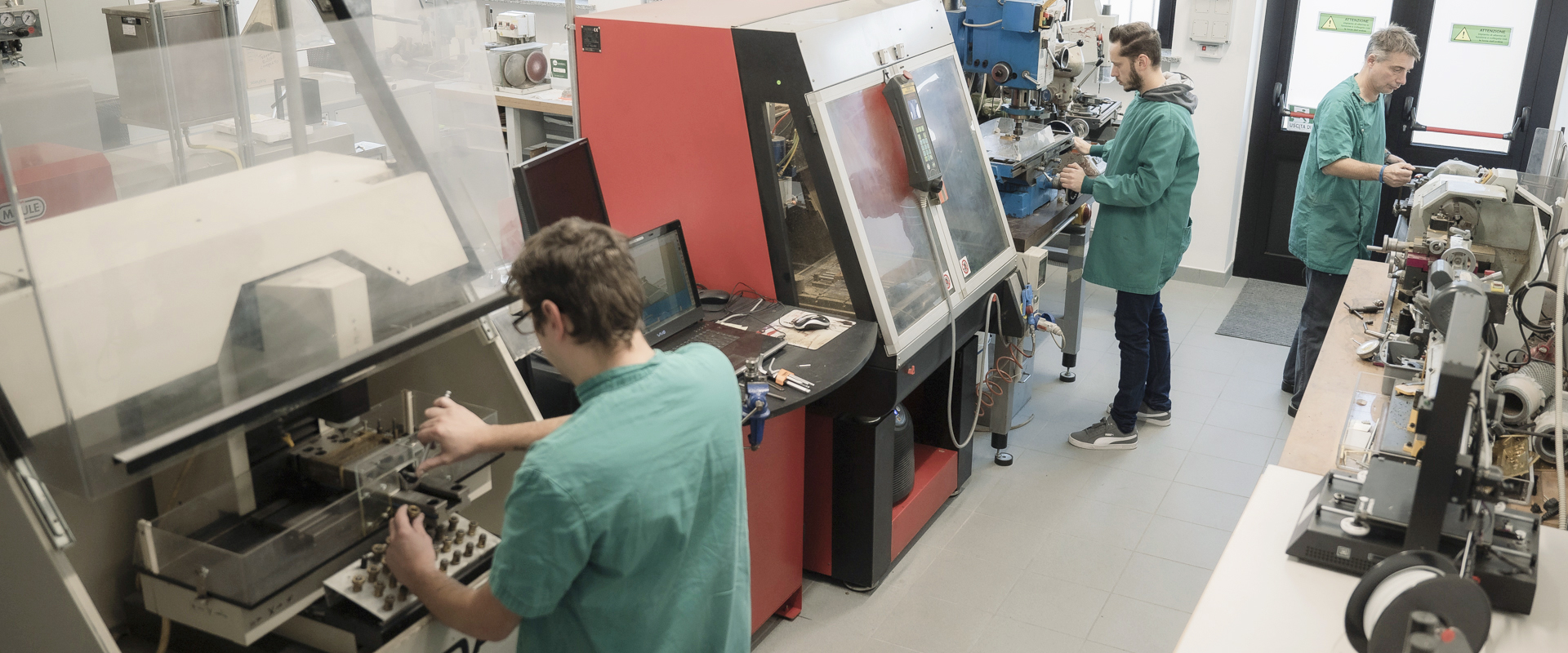

CNC Department

When it is necessary, we use mechanical processes. In-house, we have CNC machines, manual milling machines, drills, diamond cutting machines, machine tools, manual grinder polishers and automatic lapping machines.

On extending our premises, we decided to dedicate particular attention to the CNC department. We have the know-how to plan, manage and carry out every type of mechanical process and, in addition, we are investing in a development plan that will, in the short term, bring us to purchase the technology needed to upscale production.